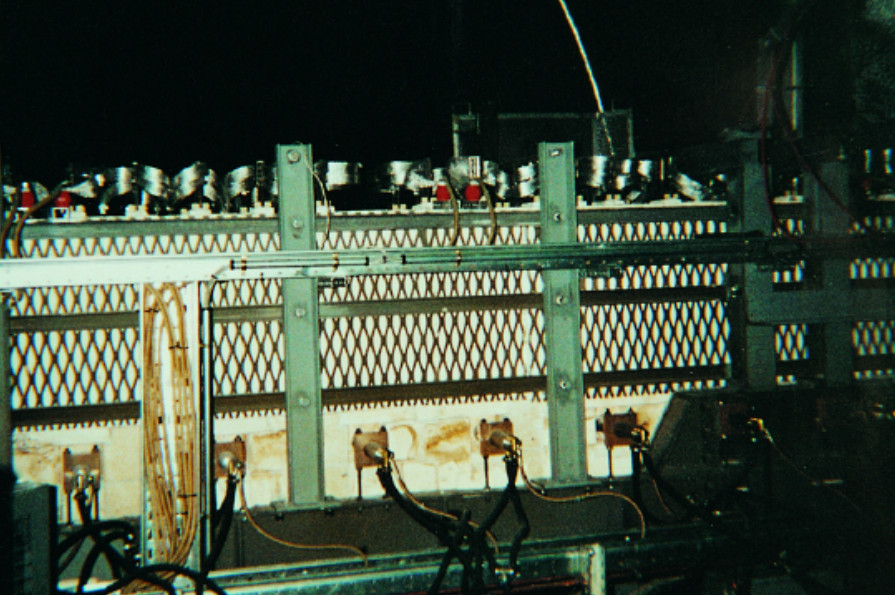

HVP Forehearth

The FIC High Vapour Pressure HVP Forehearth

FIC has once again pushed back the barriers of technological development and turned the ‘black art’ of glass conditioning into an exact and simple science.

The HVP Forehearth’s unique method of volatilisation control avoids all the defects of preceding designs such as suppressed glass levels and, with the aid of unique ‘muffle tiles’, ensures a much improved heat transfer resulting in the rapid response required during job changes.

Benefits:

The ‘uni-flux’ feature minimises temperature differences induced during glass conditioning, resulting in Iso-Thermal conditions in the equalising section.

Very thin yet strong fusedcast refractory above glass surface. Corrosion resistant.

Excellent at high temperatures.

Field proven benefits include reduced tendency for devitrification faults in hard borosilicate glass and much improved thermal homogeneity and response to job changes in opal glass.

Improved heat transfer reduces or even eliminates the need for in-glass heating, a common source of seed, in lead glass.

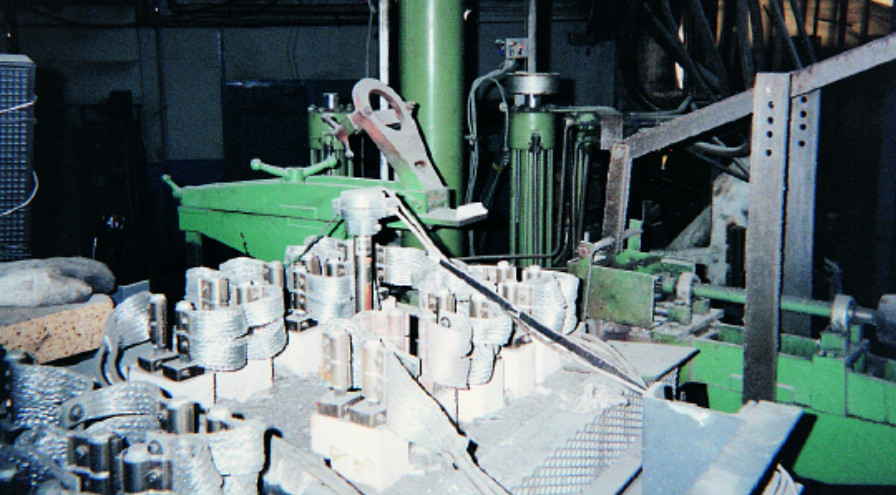

Design options include allelectric for above-glass as well as gas fired versions.

Microprocessor based control philosophy ensures super-efficiency.

Custom designed software supplied as part of control package.

Eliminates glass overflow system to remove Siliceous cords.

The unique design of the FIC HVP Forehearth embodies thin ‘muffle tiles’ made of strong, highly conductive fused-cast refractory to eliminate volatilisation losses of glasses such as lead and borosilicates and represents a major improvement in glass conditioning practice. This avoids the traditional problems encountered with previous industry designs such as cover tiles.

The uniform heat-flux design provides improved thermal homogeneity during glass conditioning, resulting in Iso-Thermal conditions in the equalising section.

Field-proven benefits include a reduced tendency for devitrification faults in hard borosilicate glass and much improved thermal homogeneity and response to job changes in opal glass.

There is reduced ‘drawdown’ and refractory contamination compared with previous industry designs.

Further Information:

-

-

Please contact us to receive more information, our latest presentation, or a quotation to purchase.